On 28 May, SKF signed a strategic cooperation agreement with Suzhou Huichuan United Power Systems Co. This is a further upgrade of the cooperation after the strategic cooperation reached last year, with ceramic ball bearings as the cornerstone of the cooperation, and at the same time expanding the business of high-speed ball bearings and tapered bearings in new energy electric drives.

Kerstin Enochsson, President of SKF Global Automotive Division, Hao Chu, President of SKF China and Northeast Asia Automotive Division, Li Juntian, Chairman and General Manager of Suzhou Huichuan United Power System Co.

uan United Power Systems Co.

Representatives of both parties signed the strategic cooperation

Kerstin Enochsson said at the signing ceremony, ‘We are pleased to further upgrade our strategic co-operation with Suzhou Huichuan United Powertrain Co. to meet the new challenges of the new energy vehicle industry. Through this cooperation, we will jointly promote technological innovation and product upgrading, and inject more vitality into the new energy vehicle industry.”

As a leading enterprise of new energy components in China, Suzhou Huichuan United Power System Co., Ltd. has been committed to becoming a global leading provider of intelligent electric vehicle components and solutions. Since the first motor of Huichuan United Power was launched on the market, SKF, as a long-term important partner, has witnessed its development, and the two sides have established a solid foundation for co-operation.

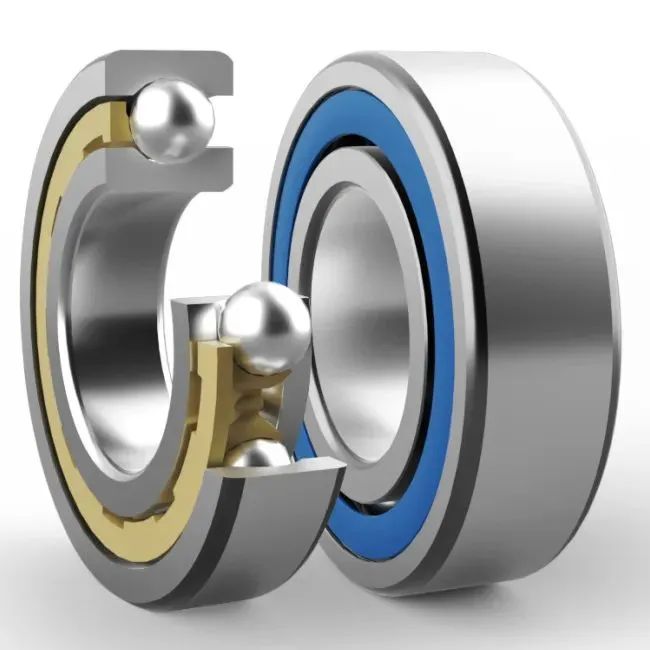

With the improvement of electric vehicle performance requirements, 800V electrical architecture will become the future development trend. At the same time, technological innovation also brings challenges to bearing products. Today, ceramic ball bearings are one of the most important technological solutions to address electrical corrosion in bearings. SKF’s proven hybrid ceramic ball bearing solution uses steel inner and outer rings with ceramic rolling elements, giving the bearing unique performance and making it the best solution for new energy electric drive bearings.

Three SKF core bearing products for new energy electric drives

Ceramic ball bearing Hybrid DGBB

The rolling bodies are made of insulating silicon nitride, which effectively prevents bearing failures due to galvanic corrosion, and are also lighter than conventional steel bearings, enabling higher limiting speeds to be achieved.

Compared to steel balls, the grease life can be increased by at least one time.

High speed deep groove ball shaft HS1.8 DGBB

The vibration and noise performance of the bearings is 100% fully inspected to guarantee the quiet performance and enhance the user experience.

The maximum speed factor can reach 1.8 million nDm, far exceeding the industry average, and can meet the maximum 30,000rpm motor speed.

Operate under the environment of -40℃ to 150℃, still can maintain excellent performance.

Low Friction Tapered Roller Bearings Low Fricition TRB

It is an important component in the speed reducer, which significantly improves the energy efficiency of the system. Under common working conditions, it can help customers improve the efficiency of the whole machine by 0.5%, extending the range and service life of new energy electric vehicles.

The new product has the same form factor as the existing product, and can achieve increased energy efficiency without changing size, life and rigidity.

In addition to the new energy electric drive business, SKF and Huichuan United Power have also reached a consensus on dual-carbon goals. SKF is fully cooperating with the carbon reduction programme that meets the requirements of Huichuan United Power and sharing relevant information to actively help both parties achieve their carbon neutrality goals.

Over the past few years, SKF has been pursuing a ‘smart’ and ‘clean’ development strategy in China, with plans to achieve net-zero emissions from its own production and operations by 2030, and net-zero emissions from its entire supply chain, from raw materials to finished products, by 2050.

In the process of cooperation with Huichuan United Power, SKF will make full use of its own experience and advantages in the field of intelligence and cleanliness, share carbon reduction solutions, make the products of both sides in the carbon reduction of the industry chain in a leading position, and jointly promote the sustainable development of the future of mobility and new energy automobile industry, improve the impact of mobility on the environment, so as to create greater environmental and economic benefits.