At present, Luoyang Shaft Research has realised the batch delivery of 5-10MW wind turbine spindle bearings, and successfully developed the first 18MW offshore wind turbine spindle bearings in China and installed them for application.

The limiting speed of a bearing is the limit value at which it can rotate continuously without generating the frictional heat that causes burns.

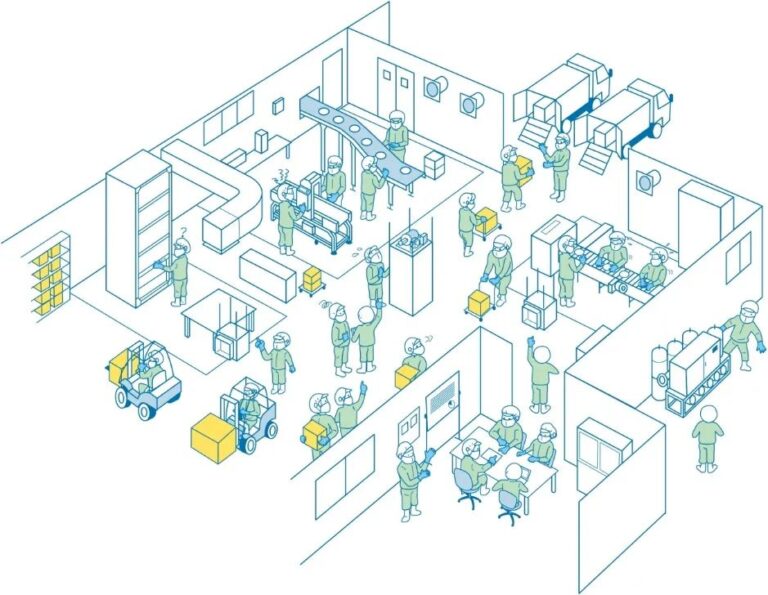

NTN will continue to strengthen cooperation with external organisations to create new businesses and advance technological innovations. At the same time, we will work to create a workplace environment that enables all types of human resources to fulfil their abilities, and to enhance the company's brand influence, in order to further strengthen our "Intelligent Management" strategy.

"The 13th Award Ceremony of NSK Prize for Outstanding Thesis Achievement in Mechanical Engineering was successfully held at the Innovation Port Campus of Xi'an Jiaotong University.

Recently, SKF (Dalian) Bearing & Precision Technology Products Co., Ltd. was honoured with the national "Green Factory" title by China's Ministry of Industry and Information Technology (MIIT)!

In recent years, Shandong Lingong adheres to the "customer-centred" principle, continues to push forward the research and development of product series, precision and differentiation, and accelerates the pace of electrification, intelligence, ecology and internationalisation, so as to better meet the needs of customers.

The meeting was hosted by Luoyang Bearing Research Institute Co., Ltd. and co-organised by Schaeffler (China) Co. More than 80 representatives of rolling bearing standard committee members, invited guests, standard drafters, secretariat and other attendees attended the meeting.

The successful completion of this package has also laid a good market foundation and customer base for the smooth launch of other high-power products of Yuchai in the future.

The high-quality completion of the PV2 solar power plant in El Dafra has greatly enhanced SINOMACH's influence in the new energy sector and created a beautiful business card for the Group in the new energy sector and high-end market.