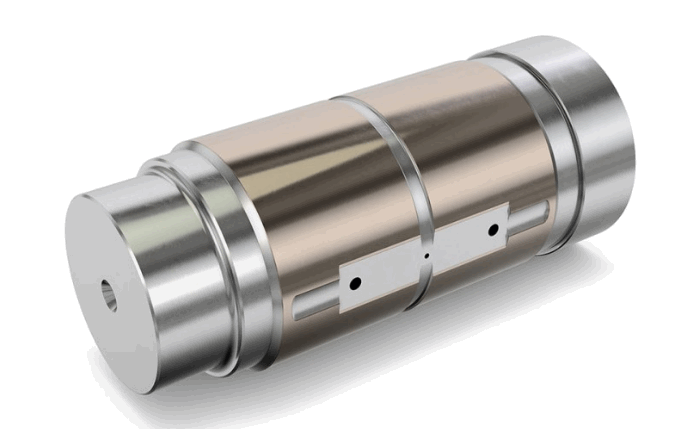

Schaeffler has introduced a sliding bearing arrangement supporting planetary gears to further strengthen its market position in wind turbine gearbox bearing solutions. Modern high-performance wind turbine gearboxes are usually equipped with multiple planetary gears to cope with the increasing torque conditions. At the recently held Wind Energy Hamburg, Germany, Schaeffler showed the advanced hydrodynamic sliding bearings. This series of sliding bearings can even help improve the power density of the gearbox in a small installation space. The thickness of the copper sliding layer of the bearing is only a few millimeters, and it is directly coated on the journal surface of the planetary gear by the additive manufacturing technology. The journal and sliding layer are bonded by chemical agents, and the service life is up to decades.

Bearing design adopts comprehensive system concept

Based on the finite element simulation process of the whole bearing system, Schaeffler uses the elastohydrodynamic (EHD) simulation tool to design the sliding bearing. The design process strives to achieve the effect of the thinnest lubricating film thickness and complete surface separation. In order to achieve zero wear condition, Schaeffler has created a detailed technical design process for customers.

Leading the development trend of wind turbine gearbox

In order to solve the problem of increasing torque density inside the gear, one of the methods adopted by the gearbox manufacturer is to increase the number of planetary gears at all levels. In this way, higher torque can be transmitted and conducted in the same installation space. However, the rolling bearing solution has the problem of space size limitation, even though the planetary gear is small, it is still not compatible with the application. The diameter of the sliding bearing solution is relatively small, which has a decisive advantage in this respect. The combination of copper bushing and planetary gear journal represents the latest level of current technology development. The pin is directly integrated into the sliding bearing using modern additive manufacturing technology, further promoting the development of this technology.