1 What should I do if the pump is not oiling?

The pump does not come out of oil should be checked:

(1) If you find that the gear pump does not come out of the oil in the host debugging, first of all, check whether the rotation direction of the gear pump is correct. Gear pumps have left, right rotation points, if the direction of rotation is not correct, the internal gear meshing volume difference formed by the pressure of oil will make the oil seal washed out and oil leakage.

(2) Whether the oil filter at the inlet end of the gear pump is clogged, such as clogging, it will cause difficulty in sucking oil or sucking oil, and produce the phenomenon that the suction hose is sucked flat.

(3) Whether the oil suction pipe is leaking.

4) Whether the pump suction height is too high.

2 Why is the oil seal washed out?

The reason why the oil seal is washed out:

(1) The gear pump is not rotating in the right direction. When the rotation of the pump is incorrect, the high-pressure oil will pass directly to the oil seal, because the general low-pressure skeleton oil seal can only withstand a maximum of 0.5 MPa pressure, so the oil seal will be washed out.

(2) Gear pump bearings are subject to axial force. Generate axial force is often associated with the gear pump shaft extension end and coupling sleeve is too tight, that is, the installation of the pump with a hammer hard hit or through the installation of screws and hard pull the pump shaft extension end of the forced pressure into the coupling sleeve. This makes the pump shaft is subject to a backward axial force, when the pump shaft rotation, this backward axial force will force the pump internal wear increased. As the internal gear pump is relying on the gear end face and sleeve end face fit sealing, when its axial sealing end face wear is serious, the pump internal axial sealing will produce a certain gap, the result is to lead to the high and low pressure oil cavity communication and make the oil seal flushed out. This situation occurs more in the dump truck industry, mainly due to irregularities in the size of the coupling sleeve on the host.

(3) The gear pump is subjected to excessive radial force. If the coaxiality of the gear pump installation is not good, it will make the pump subjected to radial force beyond the tolerance limit of the oil seal, which will cause the oil seal leakage. At the same time, it will also cause the pump internal floating bearing damage.

3 What are the reasons why the gear pump cannot build up pressure or the pressure is not enough?

Gear pumps can not establish pressure or pressure is not enough reasons:

(1) Most of this phenomenon is related to the cleanliness of the hydraulic oil. Hydraulic oil filtration accuracy is: input oil less than 60μm, return oil for 10 ~ 25μm.

The cleanliness of the oil in use does not meet the standard requirements, will accelerate the internal wear of the pump, resulting in internal leakage. Observe the failure of the gear pump sleeve and side plate, if the cleanliness of the oil used is poor, it will lead to friction on the surface of the obvious groove marks, while the normal wear of the sealing surface of the gear pump will only produce a uniform surface marks.

(2) Incorrect selection of oil.

(3) Fluid deterioration. Mineral hydraulic oil containing additives should be used to improve oxidative stability and anti-foam, to prevent oxidation of the fluid and the production of air bubbles.

4 Why is the flow rate of the gear pump not up to standard?

Reasons why the flow rate of the gear pump is not up to standard:

(1) The oil inlet filter element is too dirty and the oil suction is insufficient.

(2) The installation height of the pump is higher than the self-priming height of the pump.

(3) The suction pipe of the gear pump is too thin, resulting in high suction resistance. Generally, the maximum suction flow rate is 0.5-1.5 m/s.

(4) suction port connector leakage caused by the pump suction insufficient oil. By observing whether there are air bubbles in the oil tank, you can judge whether the system is leaking.

5 Why does the gear pump blow up?

Aluminium alloy material gear pump pressure resistance of 38 ~ 45 MPa, in its absence of manufacturing defects in the premise of the gear pump blow-up must be subjected to instantaneous high-pressure caused by. The main reasons:

(1) The oil outlet pipe is blocked by a foreign object, causing the pressure to rise indefinitely.

(2) The safety valve pressure adjustment is too high, or the opening and closing characteristics of the safety valve is poor, the response lag, so that the gear pump is not protected.

(3) If the system uses multi-way reversing valve to control the direction, some multi-way valves may be negative opening, so that will encounter due to the dead point of pressure rise and suffocate the gear pump.

6 Why is the gear pump hot?

The main reasons for gear pump heating:

1) System overload, mainly in the pressure or speed is too high.

(2) Poor oil cleanliness, internal wear increases, so that the volumetric efficiency decreases, oil leakage from the internal gap throttling and heat.

(3) The oil outlet pipe is too thin, the oil flow rate is too high, the general oil outlet flow rate is 3 to 8 m / s.

7 Gear pumps why the serious noise and pressure fluctuations?

Reasons for serious noise and pressure fluctuation of gear pump:

(1) The oil filter is blocked by dirt and cannot filter oil.

(2) The oil level is insufficient, the suction position is too high, and the suction pipe is exposed to the oil surface.

(2) the pump body and pump cover on both sides of the paper gasket did not produce a hard impact, the pump body and pump cover is not vertically sealed, the rotation of the air inhalation.

(3) The main shaft of the pump and the motor coupling is not concentric, there is twisted friction.

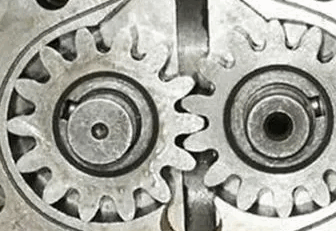

(4) Pump gear meshing precision is not enough.

8 cycloid internal gear pump what is the fault, how to rule out?

Failure 1: Large pressure fluctuation

Reason 1: The pump body and the front and rear covers are not well processed, the eccentricity error is large, or the outer rotor and the hole of the system with too large a gap. Remedy: Check the eccentricity, and ensure that the eccentricity error is within the range of 0.02mm. Outer rotor and pump body hole clearance should be 0.04-0.06mm.

Reason 2: Poor accuracy of internal and external rotor (cycloid gear) teeth. Elimination method: most of the inner and outer rotors are made of powder metallurgy, the precision of the mould affects the precision of the tooth shape, and the user can only research it.

Reason 3: The radial and endface runout of the inner and outer rotors are large. Elimination method: correct the inner and outer rotor. Make the precision meet the technical requirements.

Reason 4: The tooth side clearance of inner and outer rotor is big. Remedy: Replace the inner and outer rotor to ensure that the tooth side clearance within 0.07mm.

Reason 5: the pump is mixed into the air. Elimination method: identify the cause of air intake, remove the air.

Reason 6: the oil pump and the motor is not centred, with the uranium degree of super poor. Elimination method: correct the oil pump and motor coaxiality (0.1mm).

Reason 7: the inner and outer rotor teeth between the side gap is too large. Elimination method: repair and study to eliminate the gap.

Fault 2: Insufficient output flow

Reason 1: Axial clearance (between rotor and pump cover) is too large. Elimination method: the pump body thickness grinding? Part . Make the axial clearance within 0.03-0.04mm.

Reason 2: the inner and outer rotor teeth side clearance is too large. Elimination method: replace the inner and outer rotor (users are difficult to do).

Reason 3: the oil suction pipeline exposed in the oil tank above the oil level to the pump between the oil inlet seal is not tight, resulting in air leakage, so that the pump sucks in air, the effective suction flow is reduced. Elimination method: replace the oil pipeline seal, tighten the joint. Pipe rupture to be welded or replaced.

Reason 4: oil filter clogging. Remedy: Clean the oil filter.

Reason 5: The viscosity of the oil is too large into too small. Remedy: Replace the oil with suitable viscosity to reduce internal leakage.

Reason 6: The relief valve is stuck in a small open position. Part of the oil from the pump through the relief valve overflow back to the tank. Resulting in insufficient output flow. Elimination method: exclude the relief valve failure.

Fault 3: heat and noise

Reason 1: the outer rotor because of its outer diameter and the pump body hole with the size of the gap, resulting in friction and heat, and even the outer rotor and the pump body bite dead. Remedy: research, so that the pump body hole increased.

Reason 2: the inner and outer rotor teeth side clearance between too small or too large: too small, friction heat; too large, shaking in operation will also cause friction heat. Elimination method: research the inner and outer rotor (mounted on the pump cover to research).

Reason 3: oil viscosity is too large, oil suction resistance. Remedy: Replace the oil with suitable viscosity.

Reason 4: The precision of tooth shape is not good. Elimination method: the manufacturer can replace the inner and outer rotor, the user can only research.

Cause 5: internal and external rotor end face strain, pump cover end face strain. Elimination method: grinding inside and outside the rotor end face, wear and tear serious. First flat grinding, and then grinding, pump body thickness should also be ground to the appropriate size.

Reason 6: the pump cover on the needle bearing rupture or precision is too poor, resulting in running vibration, noise and heat. Remedy: Replace the qualified bearing.