Currently, consumers are increasingly favouring goods produced with sustainable standards. This not only reflects the widespread acceptance of the concept of environmental protection, but also becomes a key path for companies to achieve long-term sustainable development.

Bearings themselves are an efficient and sustainable product. With the continuous optimisation of their design and manufacturing processes, bearings play an increasingly important role in improving the operational efficiency of equipment and reducing energy consumption.

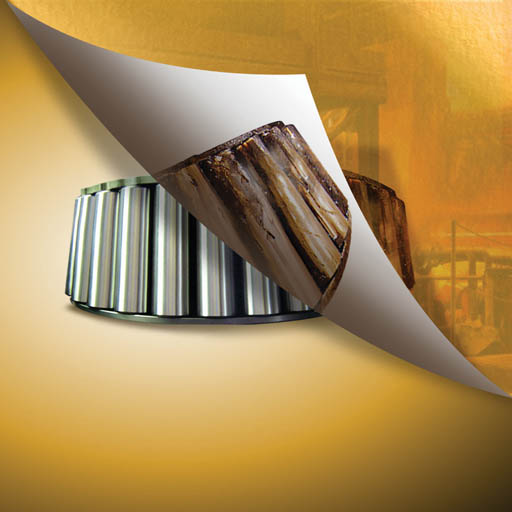

In addition, steel, the main raw material, is highly recyclable, and the bearing body has good recycling potential. Through professional repair and remanufacturing services, enterprises can not only effectively extend the service life of bearings, reduce the frequency of replacement, but also significantly reduce operating costs, providing strong support for the realisation of green and low-carbon development goals.

Why Choose Bearing Reconditioning?

A: Cost savings. A bearing reconditioned by Timken can cost 20 to 60 per cent less than a brand new bearing. If the same bearing is reconditioned twice, the cumulative savings are almost equivalent to the cost of a new set of bearings.

Shorter lead times and quicker return to service. Compared to producing a brand new bearing, reconditioning services take significantly less time, helping organisations get their equipment back up and running faster.

Which Bearings Are Suitable For Reconditioning?

A: Most bearings can be reconditioned, especially the following types:

✓ High-quality, stable performance bearings ✓ High-value, large-size or high-precision bearings (e.g., large mill bearings, paper machine bearings, etc.)

Timken offers professional reconditioning services regardless of the original manufacturer. Reconditioned bearings can perform and last as long as new bearings, and some bearings can even be reconditioned multiple times without compromising performance.

Why choose Timken Bearing Reconditioning Service?

A: More than 80 years of professional experience, trustworthy. Timken is the world’s leading bearing reconditioning expert, has a wealth of experience in serving industrial customers around the world, has established a rigorous and mature reconditioning process, and can provide differentiated reconditioning solutions according to the type of bearings, to maximize the savings of customer costs. Countless bearings reconditioned by Timken are safely operating in various metallurgical, rolling mill, paper machine, cement and other heavy industrial equipment, and have been tested and proven to be of the same quality.

How To Maximise The Value Of Bearing Reconditioning?

A: Establish an inventory cycle for cost reduction and efficiency. When new bearings are put into service, old bearings from downtime can be sent to Timken for reconditioning. When bearings need to be replaced, the reconditioned bearings are taken directly from inventory, avoiding stock-outs and expensive downtime costs. As this cycle continues, business costs will continue to decrease and operational efficiency will increase.

How Can I Tell If A Bearing Needs To Be Reconditioned?

A: Timken’s reconditioning experts can identify the type of bearing damage, analyse the root cause and recommend a suitable reconditioning solution for the customer. Common signs that a bearing is in need of reconditioning are:

✓ Judged to be in need of replacement during routine maintenance

✓ Running at temperatures exceeding 93°C

✓ Subjected to excessive vibration

✓ Sudden decrease or increase in lubrication

✓ Abnormal noise during operation

✓ Seal failure

Reconditioning is an environmentally friendly way of maintaining bearings. Compared to manufacturing new bearings, the reconditioning process significantly reduces the use of raw materials and industrial waste emissions, which is in line with the ‘dual-carbon’ policy. As an important part of cost reduction and green transformation, bearing reconditioning is gradually becoming one of the strategic choices for industrial customers to achieve sustainable development.