On 1 August 2024, SKF and RuiPai Power Technology Co., Ltd (hereinafter referred to as “RuiPai”) signed a strategic cooperation framework agreement, marking a new stage of cooperation between the two parties in the field of core components of electric drive systems for new energy vehicles.

President of SKF China and Northeast Asia Automotive Division, Mr Cu Hao, and General Manager of RuiPai Power Technology Company Limited, Mr Tang Xinhe, attended the signing ceremony of the strategic cooperation. Based on the principle of “deepening strategic co-operation and committing to win-win development”, the two sides reached a high degree of consensus on deepening co-operation, jointly addressing market challenges and enhancing the competitiveness of both sides.

In-depth Co-operation

Technology Trust

Founded by GAC Group, GAC EAN and GAC TranSwitch, and controlled by GAC EAN, RuiPai Technology focuses on the independent research and development and industrialisation of IDU electric drive system and electric control, and realises the integration of research and development, intellectual property, sales and service of independent electric drive and electric control, which is an important milestone for the company to enter into the stage of comprehensive self-research and self-production of electric drive.

In this co-operation, SKF gives full play to its advantages in technological innovation to provide Ruipai with bearing products with comprehensive competitiveness, helping Ruipai to further improve the performance and reliability of the electric drive system. Ruipai Technology has highly recognised and trusted SKF’s ultra-high-speed ball bearings, hybrid ceramic ball bearings and low-friction tapered bearings. In addition, the two sides have established a mechanism for high-level visits and business cooperation, exchange and learning, to work together to overcome technical difficulties, promote technological innovation capacity leap, and promote the smooth implementation of cooperation projects.

Specialised for new energy electric drives

Three SKF core bearing products

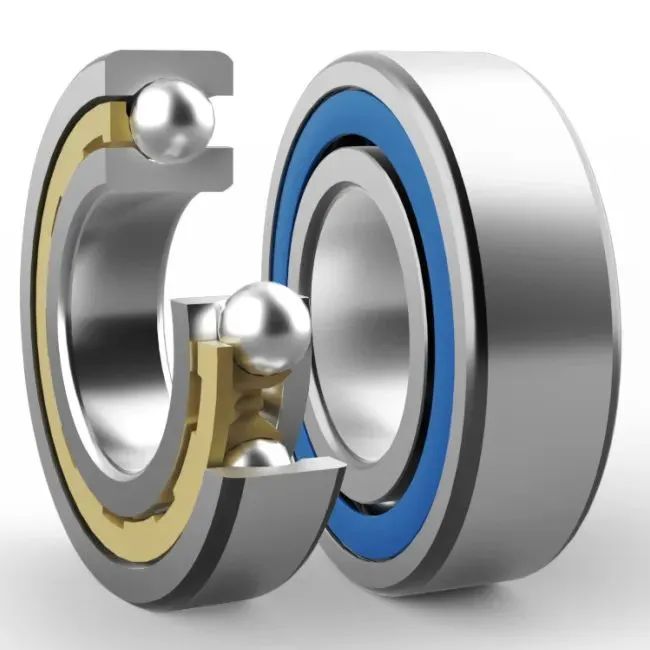

Ceramic Ball Bearing

Hybrid DGBB

The rolling elements are made of insulating silicon nitride, which prevents bearing failures due to galvanic corrosion. They are also lighter than conventional steel ball bearings, enabling higher limiting speeds to be achieved.

Compared to steel balls, the grease life is increased by at least one time.

High-speed deep groove ball bearings

HS1.8 DGBB

The vibration and noise performance of the bearings is 100% fully inspected to ensure silent performance and enhance the user experience.

The maximum speed factor can reach 1.8 million nDm, far exceeding the industry average, and can meet the maximum 30,000rpm motor speed.

Operate under the environment of -40℃ to 150℃, and still maintain excellent performance.

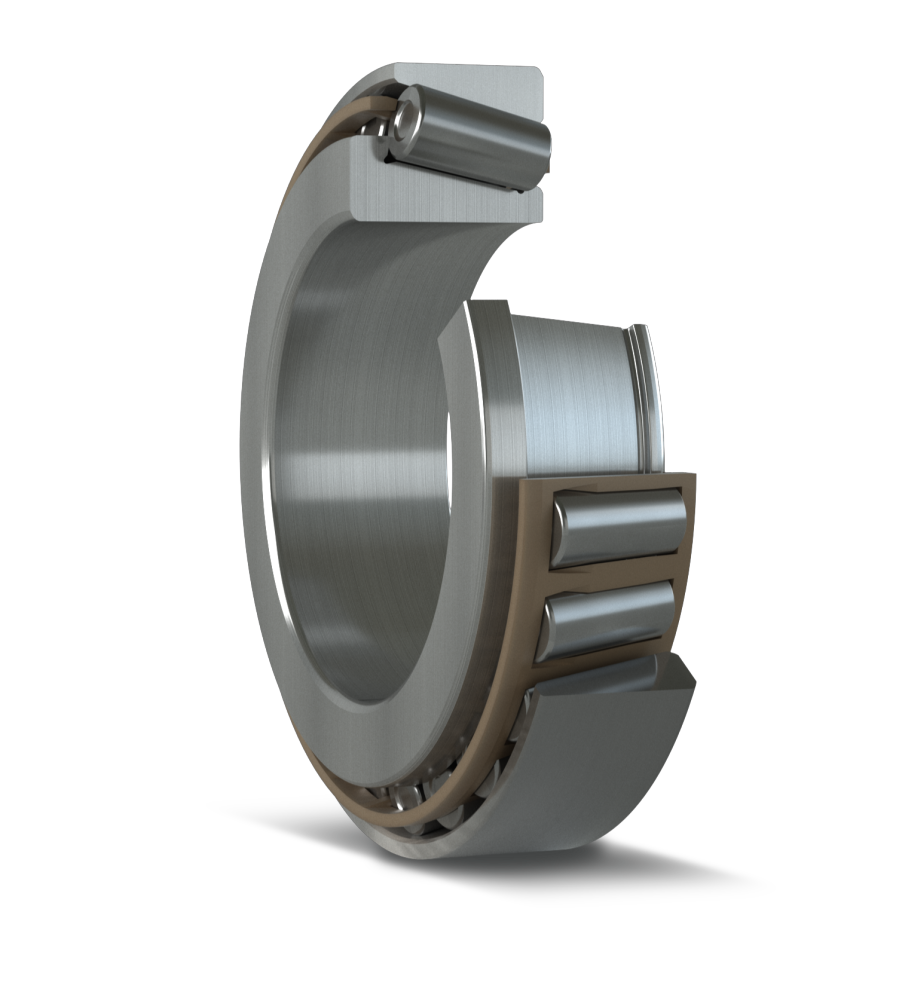

Low Friction Tapered Roller Bearings

Low Friction TRB

An important component in the speed reducer, which significantly improves the energy efficiency of the system. Under common working conditions, they can help customers improve the efficiency of the whole machine by 0.5%, extending the range and service life of new energy electric vehicles.

The new product has the same form factor as the existing product, which allows for an increase in energy efficiency without changing size, life and rigidity.

Looking to the Future

Winning the future together

The strategic co-operation between SKF and RAPID is not only a deepening and expansion of the long-term partnership between the two parties, but also a precise grasp of the future trends of the new energy vehicle market and a joint response. Both parties will work hand in hand, driven by technological innovation and oriented by market demand, to jointly promote the progress and development of electric drive system technology for new energy vehicles, create a new chapter in the field of new energy vehicles, and contribute to the achievement of the goal of global carbon neutrality.