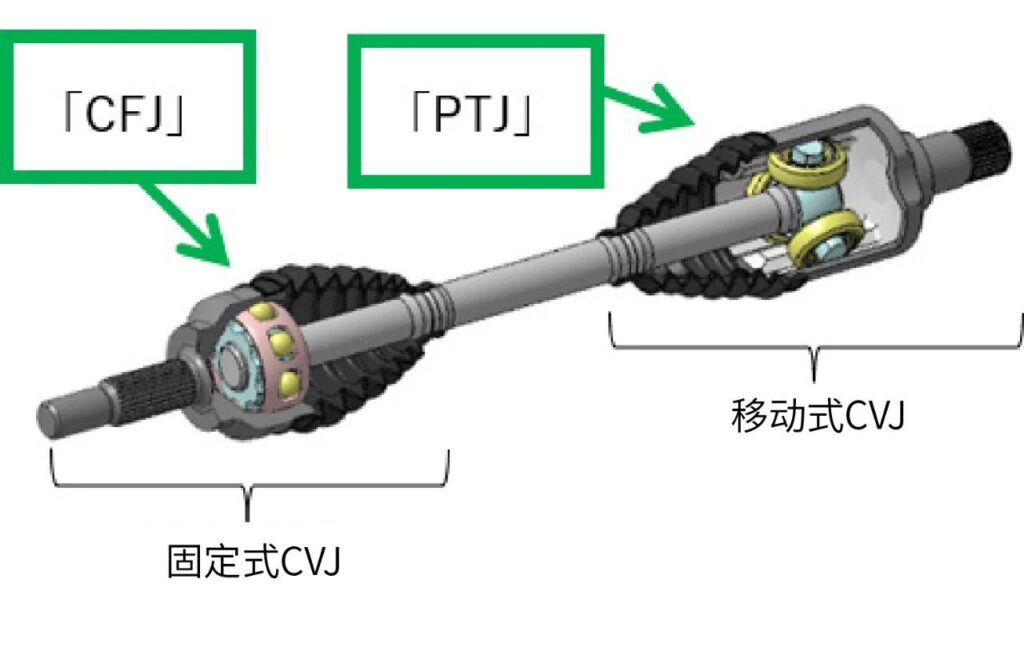

(hereinafter referred to as NTN) has begun proposing a new drive shaft solution for electric vehicles (EVs) that combines a high-efficiency fixed constant velocity joint “CFJ” with a low-vibration moving constant velocity joint “PTJ” to achieve a high level of transmission efficiency and low vibration performance. This solution achieves a high level of transmission efficiency and low vibration performance.

We recommend this product for trams seeking high transmission efficiency and NVH (noise, vibration, and comfort) performance to improve range and ride comfort.

Fixed section “CFJ”

Mobile section “PTJ”

High efficiency – low vibration drive shaft construction

01

Research and development background

The drive shaft is a component that transmits power (torque) from an electric motor or other power transmission unit to the tyre. It consists of a fixed constant velocity universal joint (CVJ) on the tyre side, a moving constant velocity universal joint (CVJ) on the powertrain side, and a shaft connecting these two CVJs.

In recent years, electric vehicles have continued to develop and gain popularity. In order to extend the range, major manufacturers are trying to reduce the electric consumption. However, when the operating angle of the drive shaft increases due to the installation of large batteries or changes in the drive unit layout to secure interior space, the torque loss rate increases.

Therefore, it is necessary to minimise the torque loss rate at larger operating angles. In addition, as power sources are replaced with electric motors and vehicles become quieter, the need to improve drive shaft NVH increases.

02

Characteristics of high-efficiency and low-vibration drive shafts

To meet these needs, NTN has introduced an excellent drive shaft that combines a high-efficiency fixed constant velocity joint “CFJ” with a low-vibration moving constant velocity joint “PTJ,” making it more suitable for electric vehicles. The “CFJ” is a CVJ with a low torque loss rate (high transmission efficiency), while the “PTJ” is characterised by reduced slip resistance (a factor that causes vibration problems in the vehicle).

Both products have been highly acclaimed by NTN customers around the world. The combination of these two products not only extends the range, but also meets the needs for low vibration and quietness that are unique to electric vehicles.

By replacing NTN’s conventional products with drive shafts combining “CFJ” and “PTJ,” torque loss can be reduced by more than 70%, and power conversion efficiency can be improved by 3.19%*1*2 In addition, when used in models with engines, CO2 emissions can be reduced by 1.71%. In addition, CO2 emissions can be reduced by 1.71 g/km*1*3 when used in models with engines.

We have already begun supplying high-efficiency, low-vibration driveshafts, which are being used in the mass production of some SUVs. We are also currently receiving a large number of orders for trams. Following the compact and lightweight rear axle-specific “R Series” driveshafts and the compact and lightweight “E Series” CVJs, NTN is accelerating the rollout of this high-value-added product to customers around the globe, which is contributing to the improvement of range and passenger comfort in trams, hybrids, and other vehicles. Improvement of passenger comfort

*(1) Comparison with NTN’s conventional “EBJ” for the fixed section and “EDJ” for the mobile section.

*2) Setting the overall vehicle weight at 1500kg, motor efficiency at 155Wh/km, and driving under WLTP conditions (CVJ mounting angle: 9 degrees).

(*3) Setting vehicle weight at 1500kg – engine efficiency at 17.5km/L, driving under WLTP conditions (CVJ mounting angle: 9 degrees)

03

High Efficiency Fixed Constant-Force Universal Joint “CFJ”

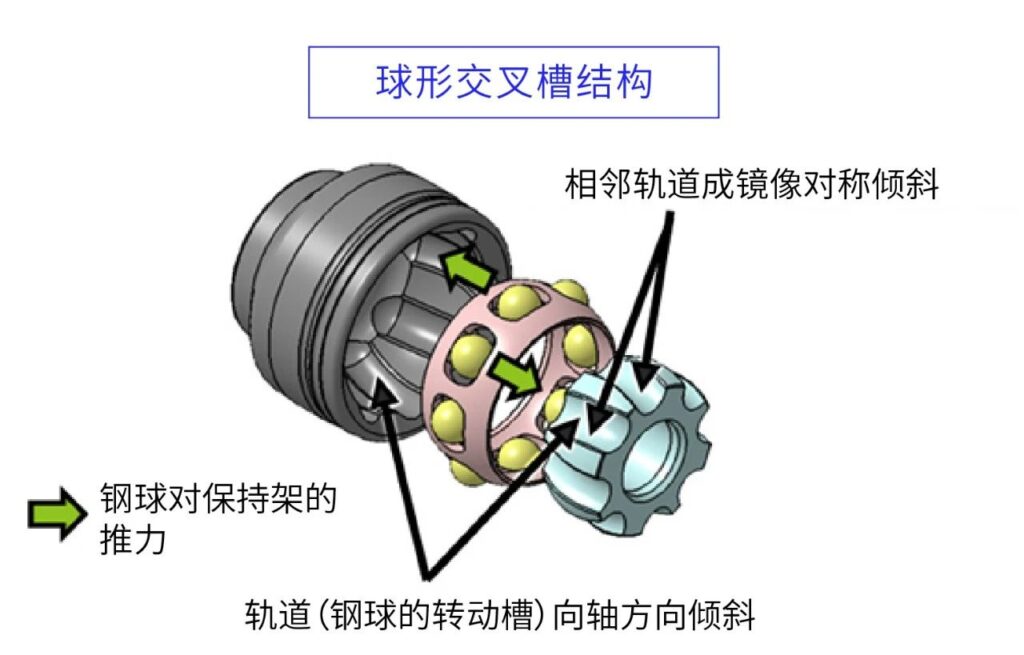

The “CFJ” is a fixed type CVJ (Constant Velocity Joint) that dramatically changes the basic structure of NTN’s conventional universal joints and adopts NTN’s proprietary “Spherical Cross Groove Structure*4”, which cancels out the forces generated by the internal components.

The torque loss rate can be reduced by 50% or more compared to NTN’s conventional products, and the torque loss rate can be significantly reduced even at higher operating angles. Its high level of transmission efficiency is recognised by automobile manufacturers around the world and has been adopted in many vehicles.

*4) This structure involves the intersection of spherical raceway grooves through the balls on the inner and outer wheels. Adjacent raceway grooves are inclined to each other, and the forces exerted by the steel balls on the inner parts are distributed alternately, thus cancelling each other out.

04

Low-vibration mobile constant velocity joint “PTJ”

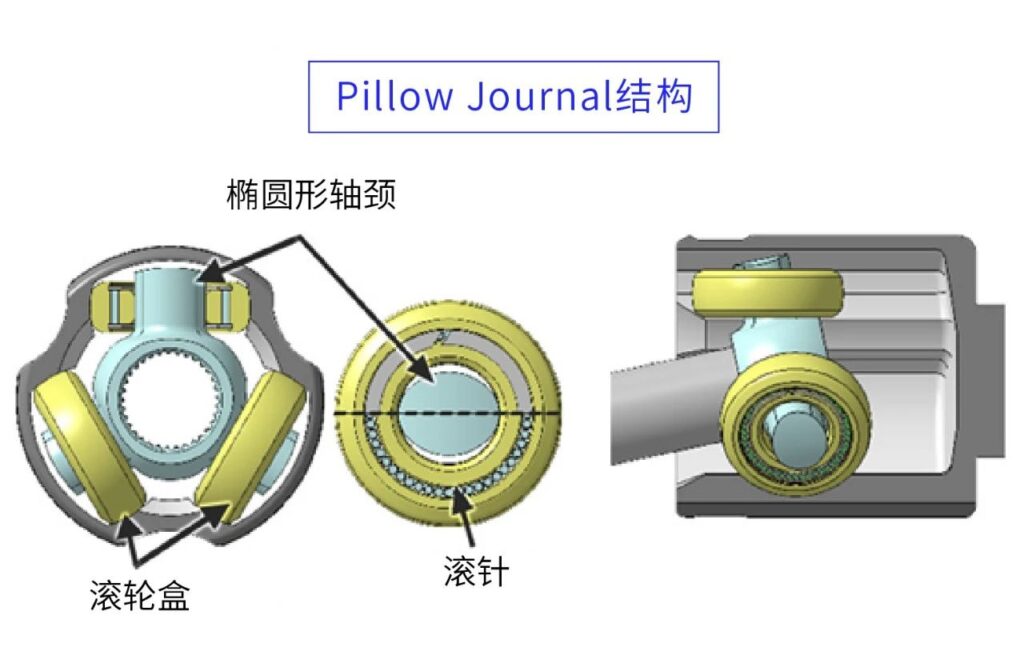

The “PTJ” is a mobile CVJ (Constant Velocity Joint) that employs NTN’s proprietary “Pillow Journal Structure”, which suppresses tilting of the internal component roller box even when the operating angle is large.

The CVJ has a high level of low vibration performance, reducing slip resistance, which causes vibration problems, to less than 50% compared to NTN’s conventional products. The CVJ has been adopted in many vehicles, such as luxury sedans, which emphasise quiet performance, and SUVs, which have a wide operating angle.