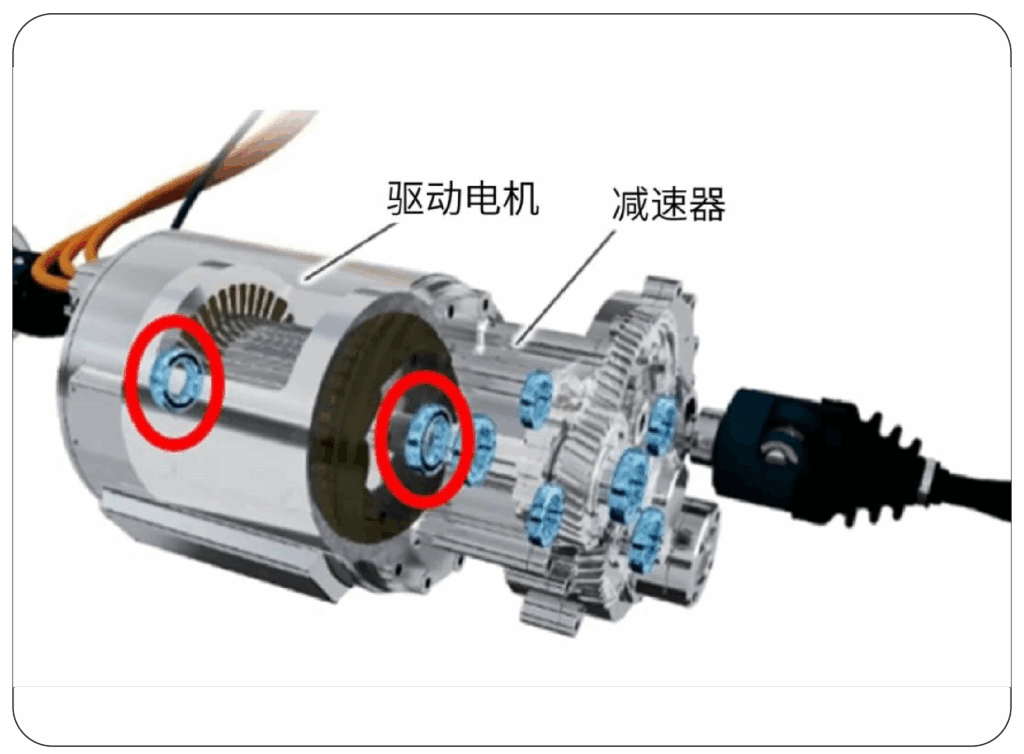

(hereinafter referred to as ‘NTN’) announced that it has begun mass production of its resin insulator bearings for the e-Axle electric vehicle.

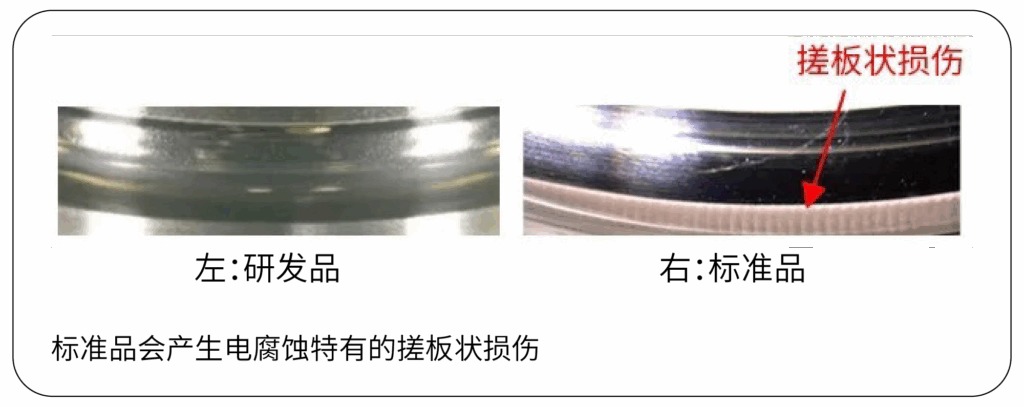

When the electric current driving the e-Axle passes through the inside of the bearing, galvanic corrosion may occur on the track surface of the bearing, causing vibration, noise, and other problems, so e-Axle bearings require galvanic corrosion countermeasures.

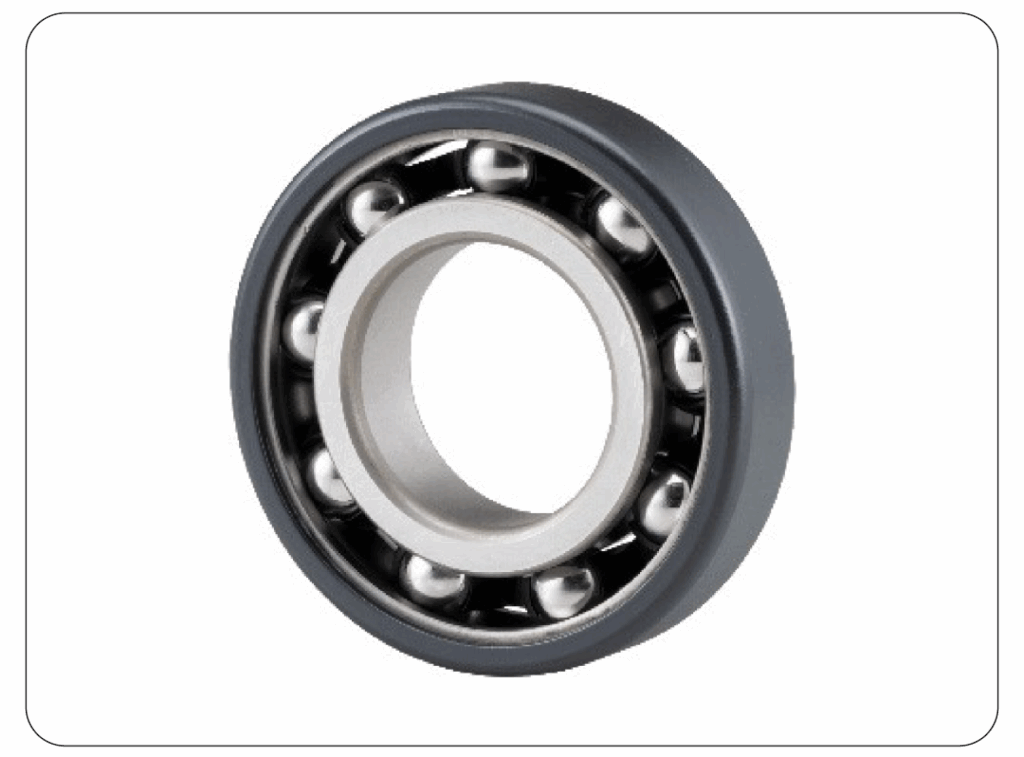

‘Resin Insulated Bearings’ prevent galvanic corrosion by injecting a resin insulating layer on the outer diameter and end surfaces of the outer ring of the bearing. The resin insulating layer has an insulating property that ensures a voltage resistance of more than 1,000V, and the material and process ensures durability, a wide range of operating temperatures, and resistance to peeling off during assembly.

This product won a bid for mass production in the e-Axle system for EV vehicles of an overseas automobile manufacturer, and NTN recommended resin-insulated bearings from its lineup of corrosion-resistant products based on the customer’s conditions of use. The bearings passed the customer’s insulation and durability evaluations, and were finally mass-produced.

High-voltage is accelerating in order to achieve long range and fast charging of EV batteries, and 800V systems are expected to be gradually popularised, but higher battery voltages will exacerbate galvanic corrosion of bearings.

This product has a voltage resistance of 1000V or more, making it suitable for 800V battery systems, and the range of applications is expected to continue to expand in the future.

In addition to this product, NTN is also developing electrically conductive sealed ring bearings to expand its range of galvanic corrosion-resistant products.

NTN is also working on the mechanism of the process from energisation damage to the generation of vibration and noise, as well as methods for predicting the life of galvanic corrosion. As system requirements for galvanic corrosion resistance increase, NTN will provide optimal solutions based on customer-specific application scenarios.

Product Characteristics

1. Electrical corrosion resistance

The resin injected into the outer diameter and end surfaces of the bearing has excellent insulating properties and reduces the amount of current passing through the bearing, and it has insulating properties that withstand a voltage of 1,000V or more. This product is able to cope with the 800V battery voltage*1*1 that will become popular in the market. The preset condition is that the bearing for e-Axle can withstand a voltage no higher than 10% of the battery voltage.

2.Durability

Resin materials are prone to cracking due to temperature changes. However, the raw material of this product maintains its strength even when the temperature changes drastically, and the moulding method retains the overall high strength of the coating, thus ensuring the durability of the e-Axle under the temperature environment.