Can you imagine building a ‘lunar energy base’ on Earth? This sci-fi idea is becoming a reality in the Faroe Islands. Over the past year, global bearing manufacturer SKF has been working closely with Minesto, a pioneer in the development of ocean energy, to develop the ‘Luna LUNA 12’ kite system, which converts tidal energy into renewable energy.

SKF’s innovative tool for efficient development

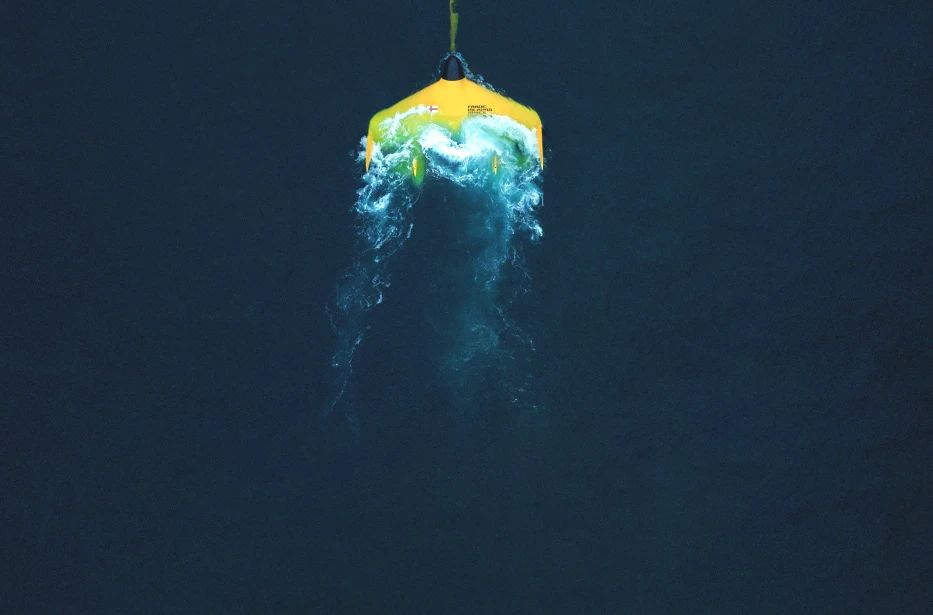

The ‘Luna LUNA 12’ kite system, also known as ‘Dragon 12’, is an energy device that is installed and fixed on the seabed. It operates under harsh conditions and puts materials and components under enormous stress.

To help advance the project, SKF not only provided advanced bearing technology and products for the rudders, generators and turbines of the kite system. It also used its professional software tools to provide comprehensive support for the development of Luna 12.

➣ SKF Sensors

To ensure stable equipment operation, SKF sensors are installed in the bearings on the turbine shafts for real-time monitoring of equipment operating conditions. Through vibration monitoring and temperature monitoring, the turbine is monitored to detect abnormal equipment frequencies and enable planned maintenance to avoid bearing damage and unplanned downtime.

In addition to understanding the health of the bearings, the sensors also obtain information on the operation of peripheral systems, enabling precise control of the entire system.

➣ SKF SimPro Quick software tool

SimPro Quick is the SKF software tool for evaluating and optimising bearing configurations. It enables a detailed evaluation of the performance of bearing configurations based on user-specific requirements and conditions. The SKF SimPro Quick software tool played an important role in the development of the Luna 12. The tool enables the rapid creation of calculation models for turbines, rudders and generators, helping engineers to evaluate and optimise bearing configurations.

Minesto engineers can use SimPro Quick to generate their own calculation models and communicate optimisation options to SKF engineers, which greatly improves productivity.

SKF ‘Product Selection’ tool

In addition, SKF’s ‘Product Selection’ tool played a key role in the early stages of the project. By entering the bearing type and operating conditions, the tool calculates important parameters such as minimum load, bearing load, grease life, supplemental lubrication intervals and rated bearing life. It even estimates the carbon dioxide emissions of SKF products, helping engineers compare different solutions from both a technical and sustainability perspective.

Yvonne Rydberg, SKF application engineer, says Product Select is very quick to get started and very powerful. In many cases, you don’t need other software tools to design a bearing configuration.

A win-win for technology and sustainability

From high-quality products such as bearings and turning seals to innovative tools such as sensors, SimPro Quick and Product Select, SKF has ensured the stable operation of the Luna 12 project from design to operation and maintenance.

Bernt Erik Westre, Minesto’s chief technology officer, says that by working with SKF, they are able to accurately assess bearing performance and obtain key information to guide subsequent work. Ensuring that the design is correct from the outset not only saves money, but also reduces the impact on the environment.

The products and technologies used by SKF in the Faroe Islands space programme demonstrate not only its leadership in bearing manufacturing, but also its commitment to sustainability.

As a global company committed to more innovative and sustainable development. In the future, SKF will continue to adhere to the brand concept of ‘Resistance – To the distance’ and create unlimited possibilities with limited resources.