A high value-added product that suppresses dust generated by grease to the utmost while improving low-torque performance is now in mass production for major motor manufacturers.

By suppressing the adhesion of grease components to encoders and brake discs used to detect motor rotation angles, this product helps improve the reliability of servo motor control.

NTN Corporation

Low-dust bearings for servo motors

NTN Corporation (hereinafter referred to as NTN) has begun mass production of ‘low-dust bearings for servo motors.’ These bearings, which are widely used in servo motors for industrial robots, machine tools, semiconductor manufacturing equipment, and other fields, significantly reduce dust* generated by bearings and rotational torque.

*The evaporation or formation of oil droplets from the lubricant (lubricating grease) used inside the bearing, which may leak to the exterior of the bearing.

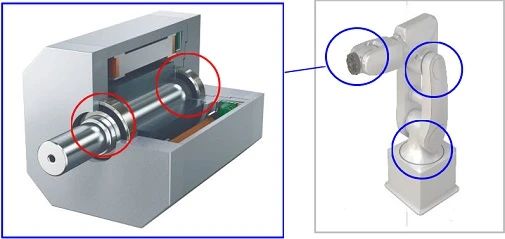

Application areas of the product in industrial robot servo motors

Servo motors, equipped with rotation detectors (sensors, encoders) and brake devices, enable high-precision control of speed and angle, making them widely used in industrial robots, machine tools, and other industrial equipment requiring precise operation. However, dust generated from the oil components in the lubricant used in bearings can adhere to the encoder, reducing detection accuracy; if it adheres to the brake disc, it may also affect braking performance. Therefore, bearings for servo motors have always been required to suppress the generation of such dust.

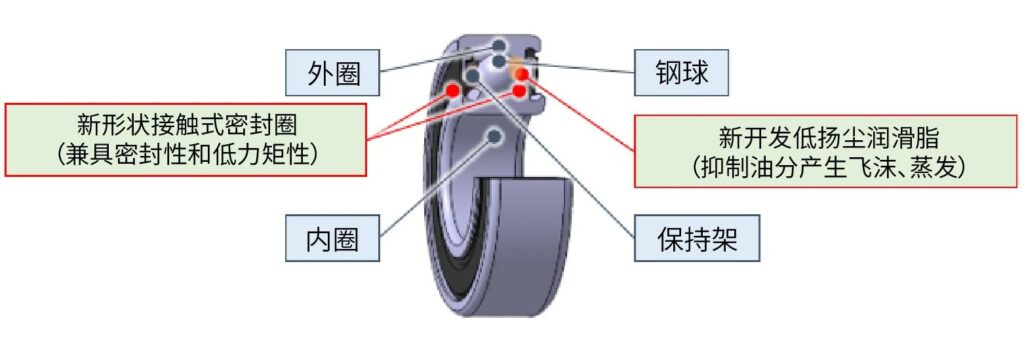

NTN’s newly developed ‘low-dust servo motor bearings’ incorporate two innovations: first, a new low-dust grease that significantly reduces dust generation by adjusting the composition and ratio of its components; second, a newly designed seal ring with enhanced sealing performance. These improvements reduce dust generation by approximately 90% compared to conventional products. Additionally, the newly designed seal ring achieves approximately 50% lower torque compared to conventional products while maintaining sealing performance through optimised shape design.

This product not only enhances the reliability of servo motor control by significantly suppressing dust generation but also gains recognition for its high durability, enabling long-term stable use while suppressing rotational torque. It has recently been adopted by a major motor manufacturer and commenced mass production.

Servo motors, which enable high-precision rotational control, have seen sustained growth in demand centred on industrial robots and machine tools in recent years. Servo motors used for joint drives in industrial robots and humanoid robots require higher rotational speeds and accelerations at the joint shafts, leading to increased demands for miniaturisation and high power density. This product significantly reduces bearing dust, enabling servo motors to achieve miniaturisation without the need for sealing devices. Additionally, by reducing torque, it enhances the power density of servo motors.

NTN will continue to develop high-value-added products such as this product and the ‘high-speed servo motor deep groove ball bearing’ with high-speed and low-vibration performance, further contributing to the performance enhancement of servo motors.

Features of the new product (compared to NTN’s standard products)

1. Low dust generation Reduces dust generation by approximately 90%

2. Low torque Reduces torque by approximately 50%

Applications

Targeted at servo motors for industrial robots, machine tools, semiconductor manufacturing equipment, and other applications.